Description

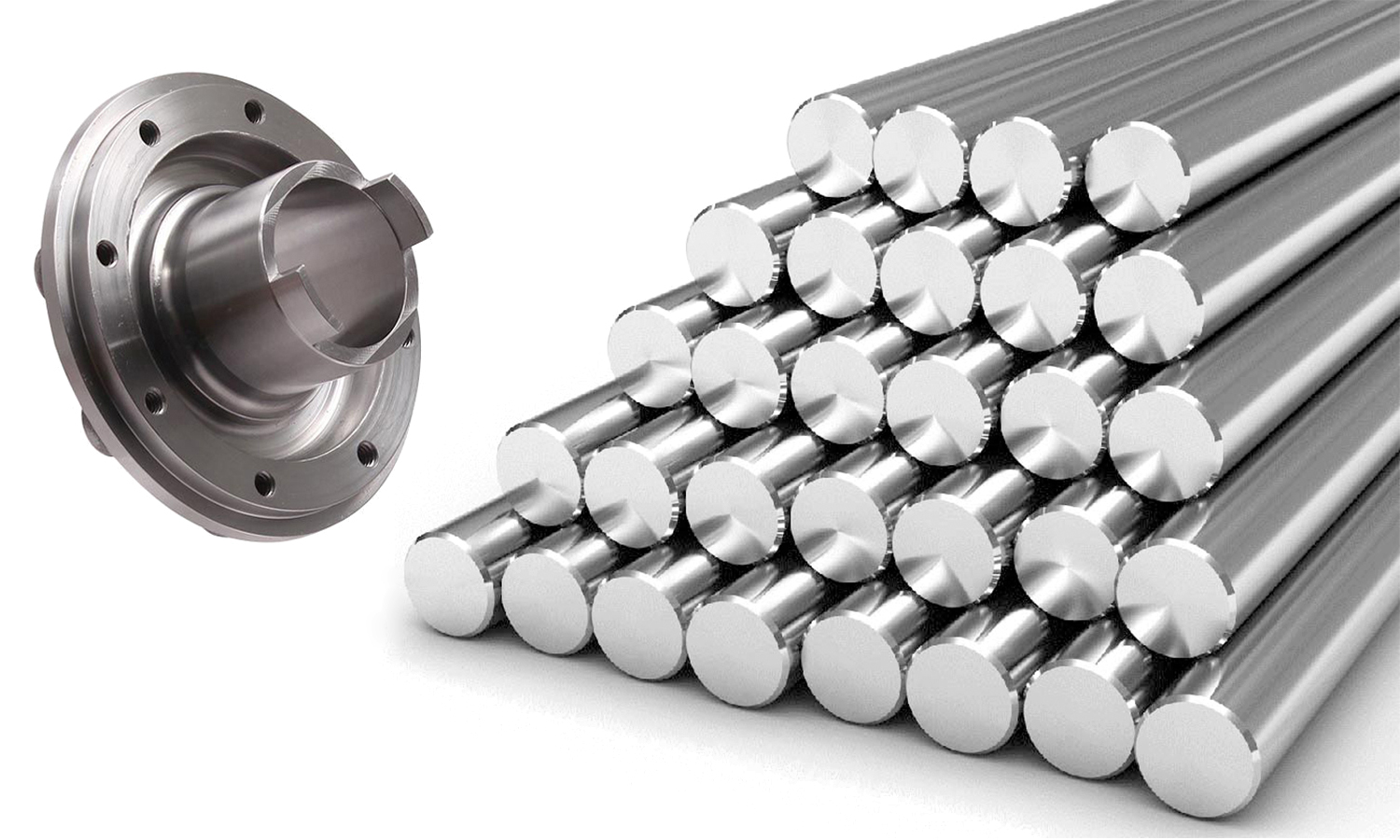

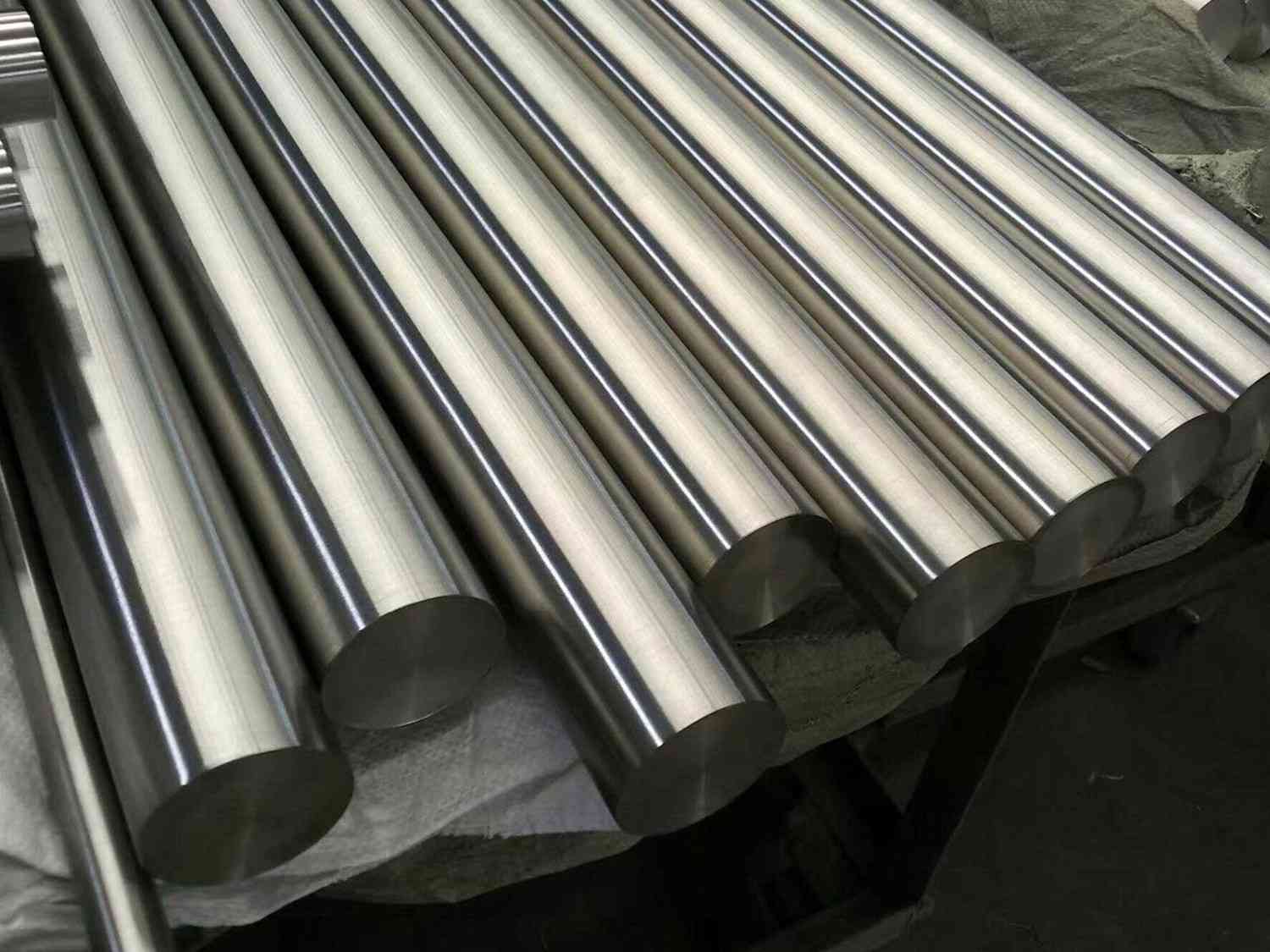

Titanium Grade 5, also known as Ti-6Al-4V, is one of the most widely used titanium alloys, renowned for its exceptional strength-to-weight ratio and corrosion resistance. Composed of 90% titanium, 6% aluminum, and 4% vanadium, this alloy combines excellent mechanical properties with good weldability and machinability. Its high tensile strength makes it ideal for demanding applications in aerospace, automotive, and biomedical industries, where weight savings and durability are critical. Additionally, Ti-6Al-4V demonstrates superior resistance to oxidation and high temperature, making it suitable for components exposed to extreme environments, such as jet engine parts and surgical implants.

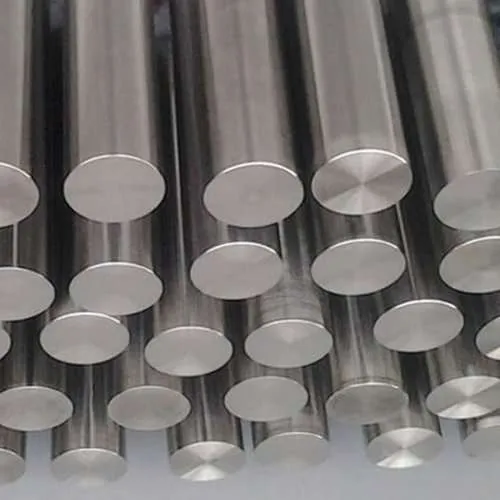

In contrast, Monel 400 is a nickel-copper alloy that exhibits impressive resistance to corrosion, especially in marine environments where exposure to seawater and acidic conditions is prevalent. Composed primarily of nickel (about 67%) and copper (approximately 33%), Monel 400 demonstrates excellent mechanical properties and good weldability, making it a popular choice in chemical processing, oil and gas extraction, and marine applications. Its ability to withstand stress and corrosion from harsh chemicals, alongside its durability in high-temperature conditions, positions Monel 400 as a reliable material for components like valves, pumps, and piping systems.

The combination of Titanium Grade 5 and Monel 400 showcases the versatility and robustness of these materials across various industrial sectors. While Ti-6Al-4V excels in applications requiring lightweight strength and resilience, Monel 400 proves indispensable in environments where corrosion resistance is paramount. Together, these alloys highlight the importance of material selection tailored to specific operational challenges, ultimately enhancing performance and longevity in demanding applications.