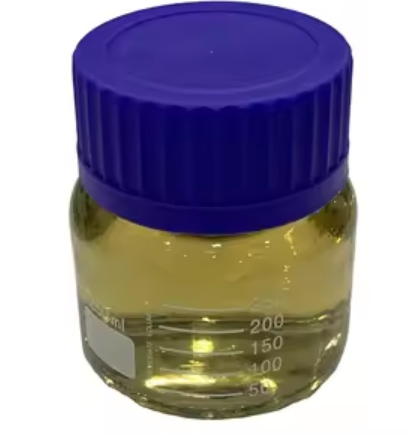

Description

What is phenolic resin and how does it work?

Phenolic resins are non-degradable plastics from the group of thermosets. The resin is obtained by polycondensation of phenol and formaldehyde. both substances are not physiologically harmless and phenolic resins are therefore regarded as contact allergens. Therefore, they cannot be used in the food sector (and it is not considered to be food-safe).

Phenolic resins are characterized by their special properties, because they can be used to produce the stable and temperature-resistant material Phenoplast – a thermosetting plastic that can be used for a wide range of industrial applications.

The odorless and tasteless resins impress with their outstanding properties because they are extremely break-resistant when cured and resistant to many other chemicals – e.g., water, acids or organic solvents. In addition, they are heat-resistant, flame-retardant, and therefore have a high dimensional stability to heat. In addition, phenolic resins are waterproof.

Furthermore, phenolic formaldehyde resins have a low tendency to creep (also: retardation) and at the same time high rigidity. As a result, phenolic resins hardly deform under constant load over time and under various temperature influences. The linear thermal expansion also remains low.

Phenolic resins are also considered poor conductors of heat and electricity. It has no melting point but only a decomposing point in the temperature zone of 220 °C (428 °F) and above.

What is phenolic resin used for?

There are a huge variety of applications within the industry. Amongst others, it is often used as insulating material since it is highly heat resistant and has a low thermal conductivity.

Additionally, it can e.g., be used within or for :

- adhesives

- foundry

- grinding wheels

- abrasives

- rubber

- rubber adhesive

- brake pads

- plywood