Description

Powering the Depths: The Crucial Role of HV Rubber Cables in Mining and Tunneling

Mining and tunneling operations represent some of the most demanding environments for any equipment, and high-voltage (HV) power cables are no exception. These cables are the lifeblood of these operations, delivering the electricity necessary for powering critical machinery, lighting, and ventilation systems that keep workers safe and operations running smoothly. However, the abrasive conditions, confined spaces, and potential for physical damage pose unique challenges, demanding robust and reliable cable solutions. This is where HV rubber cables, specifically designed for these applications, step in.

The Challenges of Mining and Tunneling Environments:

Before delving into the specifics of HV rubber cables, it’s crucial to understand the harsh realities they face:

- Physical Stress: Operations involve heavy machinery, blasting, and constant movement, leading to a high risk of abrasion, impacts, and crushing.

- Chemical Exposure: Mines and tunnels often contain corrosive substances like acidic water, oils, and chemicals that can degrade cable insulation and conductors.

- Extreme Temperatures: Depending on the location and depth, mines and tunnels can experience extreme temperatures, both hot and cold, requiring cables with a wide operating temperature range.

- Confined Spaces: The tight spaces of mines and tunnels demand flexible cables that can be easily routed and installed, minimizing the risk of damage during installation and operation.

- Safety Concerns: Electrical faults can have devastating consequences in confined and often hazardous environments. Robust safety features are paramount.

Why HV Rubber Cables Excel in These Demanding Environments:

HV rubber cables are specifically engineered to meet the challenges outlined above, offering a superior alternative to other types of cables in mining and tunneling applications:

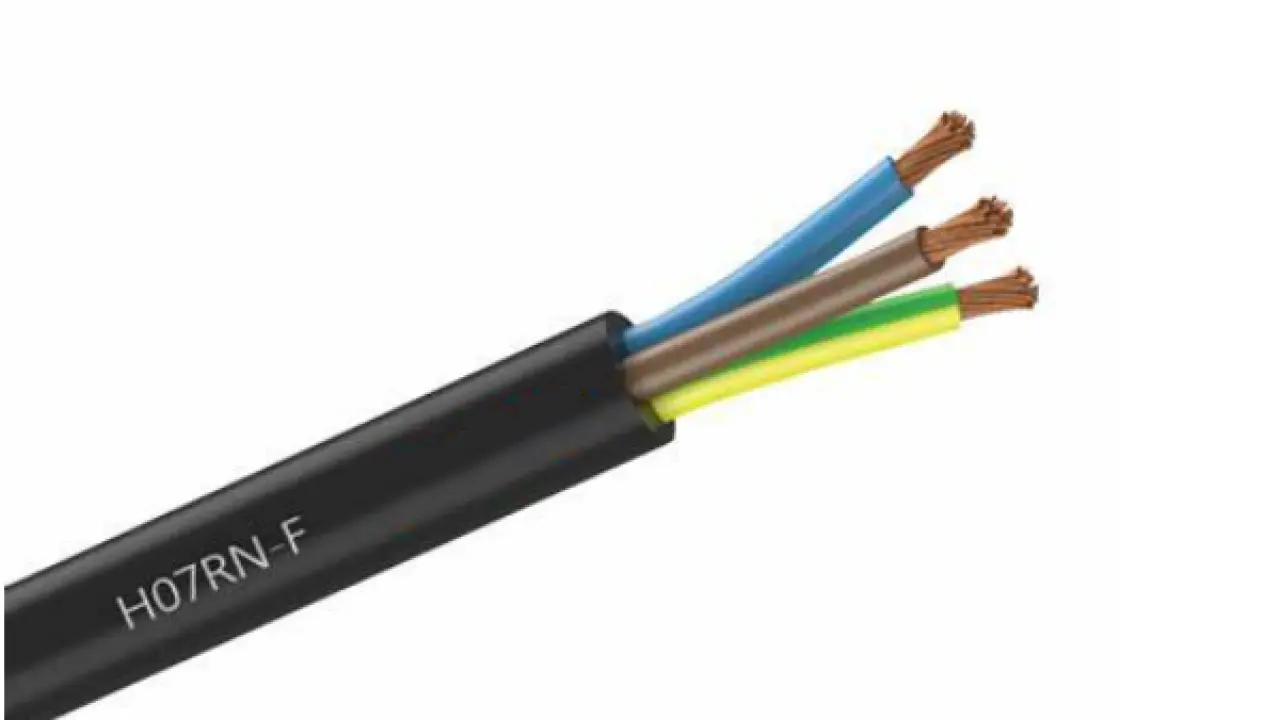

- Superior Flexibility: Rubber insulation compounds, particularly those with ethylene propylene rubber (EPR) or chloroprene rubber (CR) bases, provide excellent flexibility, allowing for tight bends and easy handling in confined spaces. This reduces the risk of damage during installation and operation.

- Robust Mechanical Protection: The tough rubber jacket offers superior abrasion resistance, impact resistance, and tear resistance compared to other cable types. This helps protect the cable from damage caused by rocks, machinery, and other hazards.

- Enhanced Chemical Resistance: Rubber compounds can be formulated to resist a wide range of chemicals commonly found in mining and tunneling environments, preventing degradation and extending cable lifespan.

- Wide Temperature Range: HV rubber cables are designed to operate effectively in a wide range of temperatures, ensuring reliable performance in both extremely hot and cold conditions.

- Excellent Electrical Properties: Despite their flexibility and robustness, HV rubber cables maintain excellent electrical properties, ensuring efficient and safe power transmission.

- Safety Features: These cables often incorporate safety features such as enhanced grounding systems, flame retardant properties, and monitoring capabilities to minimize the risk of electrical hazards.

Applications in Mining and Tunneling:

HV rubber cables are used in a wide range of applications within mining and tunneling operations, including:

- Powering Mining Equipment: Supplying power to excavators, drilling rigs, loaders, and other heavy machinery.

- Ventilation Systems: Providing power to fans and other components of ventilation systems that ensure a safe and breathable atmosphere.

- Lighting Systems: Powering lighting systems that illuminate the work areas and improve visibility.

- Pumping Systems: Supplying power to pumps that remove water and other fluids from the mine or tunnel.

- Conveyor Systems: Powering conveyor belts that transport materials within the mine or tunnel.

- Specialized Equipment: Powering specialized equipment used for specific tasks, such as rock bolting or shotcreting.

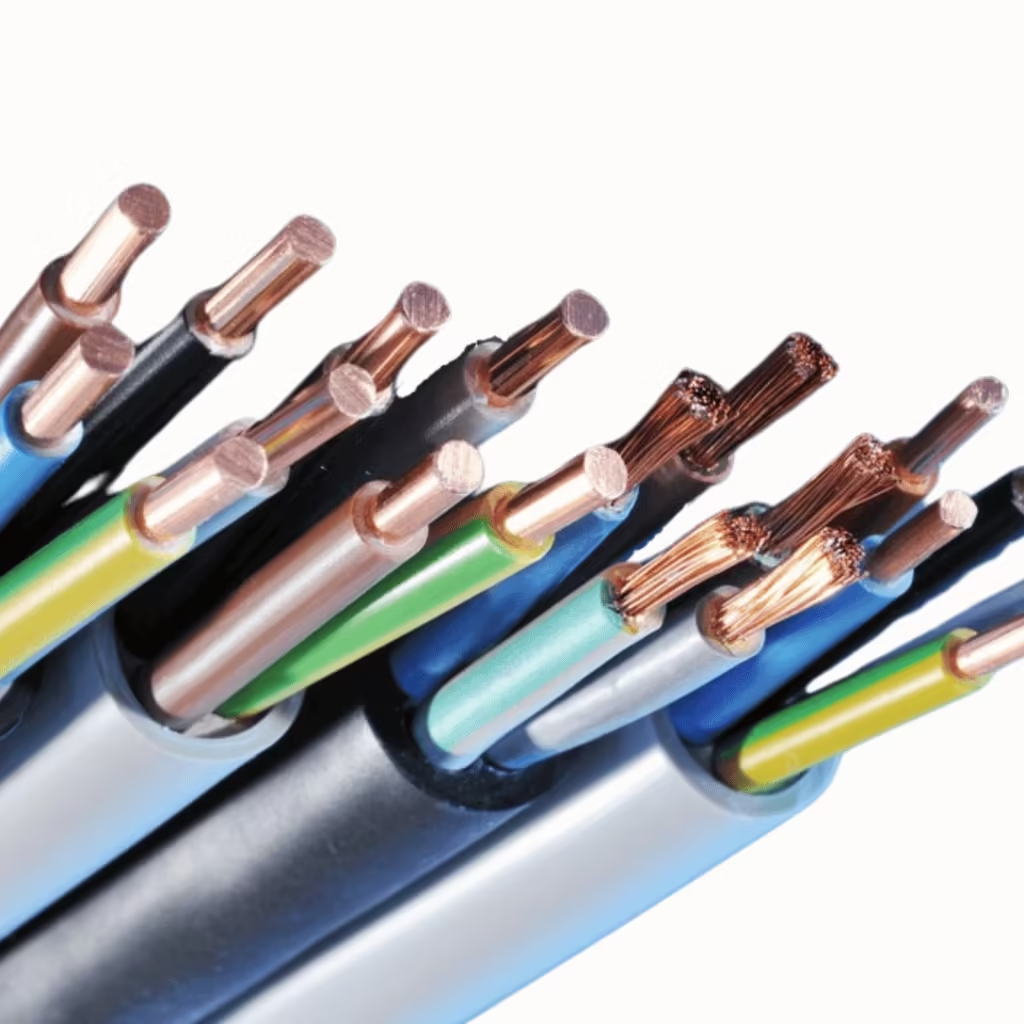

Choosing the Right HV Rubber Cable:

Selecting the appropriate HV rubber cable for a specific application requires careful consideration of several factors, including:

- Voltage Rating: Select a cable with a voltage rating that is suitable for the application.

- Current Carrying Capacity: Ensure the cable has sufficient current carrying capacity to handle the anticipated load.

- Environmental Conditions: Consider the specific environmental conditions, such as temperature, chemical exposure, and physical stress.

- Installation Requirements: Factor in the ease of installation and the flexibility required for routing the cable.

- Safety Standards: Ensure the cable meets all relevant safety standards and regulations.

Conclusion:

HV rubber cables play a vital role in powering the challenging environments of mining and tunneling operations. Their superior flexibility, robustness, and chemical resistance make them the ideal choice for these demanding applications. By understanding the specific requirements of each application and carefully selecting the appropriate cable, operators can ensure the safe and reliable delivery of power, maximizing productivity and minimizing downtime in these critical industries. Investing in high-quality HV rubber cables is an investment in safety, efficiency, and the long-term success of mining and tunneling projects.