Description

Methyl Methacrylate (MMA), easily entering into the reaction of accession with a wide range of organic and inorganic substances, is used for the synthesis of organic low molecular weight substances.

Product type: Methacrylate Monomer (Precursor)

Features & Benefits:

- Hydrophobicity

- Hardness

- Adhesion

- Weatherability

Applications areas:

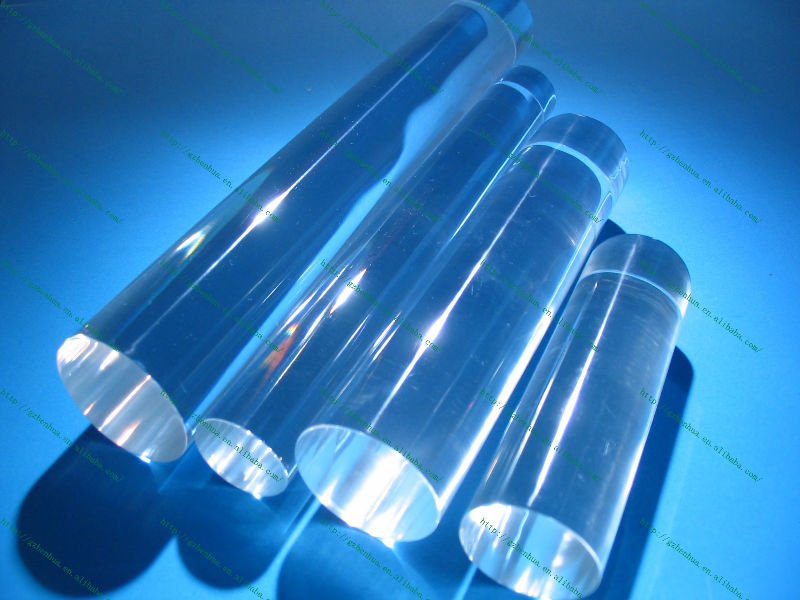

- Methyl Methacrylate (MMA) is used in the manufacture of organic glass, coatings, lubricating oil additives, plastics, adhesives, wood wetting agents, electric coil soak, ion exchange resin, paper glazing agents, textile auxiliaries, leather treatment agents, dyeing auxiliaries, and insulation filling materials.

It is applied in the production of:

- Acryl resins

- Coating resins

- Molding materials

- Latex paints

- Glues & sealants

- Emulsions

- Modifiers

- Impregnation agents

Chemical Properties:

-

Puritymin. 99.8%

-

Acid Valuemax. 0.005%

-

Water contentmax. 0.05%

-

Color APHAmax. 10

Physical Properties:

-

AppearanceClear

-

Physical formLiquid

-

OdorOdourless

-

Molecular weight100 g/mol

-

Density0,942 – 0,946 g/cm3 at 20 °C

-

Boiling Point101 °C

-

Freezing Point– 48 °C

-

Flash point101 °C

-

Melting Point– 48 °C

Storage & Handling:

To avoid polymerization, Methyl Methacrylate (MMA) should always be stored in air and not under inert gases. For the effective functioning of the stabilizer, the presence of oxygen is necessary. MMA must contain a stabilizer and be stored at a temperature not exceeding 35 °C. Under such conditions, product stability is maintained for 1 year. In order to minimize the likelihood of excess storage, the storage procedure must strictly follow the first-come-first-go principle. When storing Methyl Methacrylate (MMA) for more than 4 weeks, it is advisable to replenish the content of dissolved oxygen. Methyl Methacrylate (MMA) transportation can be carried out by rail, road, sea, river transport, in accordance with the rules for the transport of goods in force on this type of transport.