Description

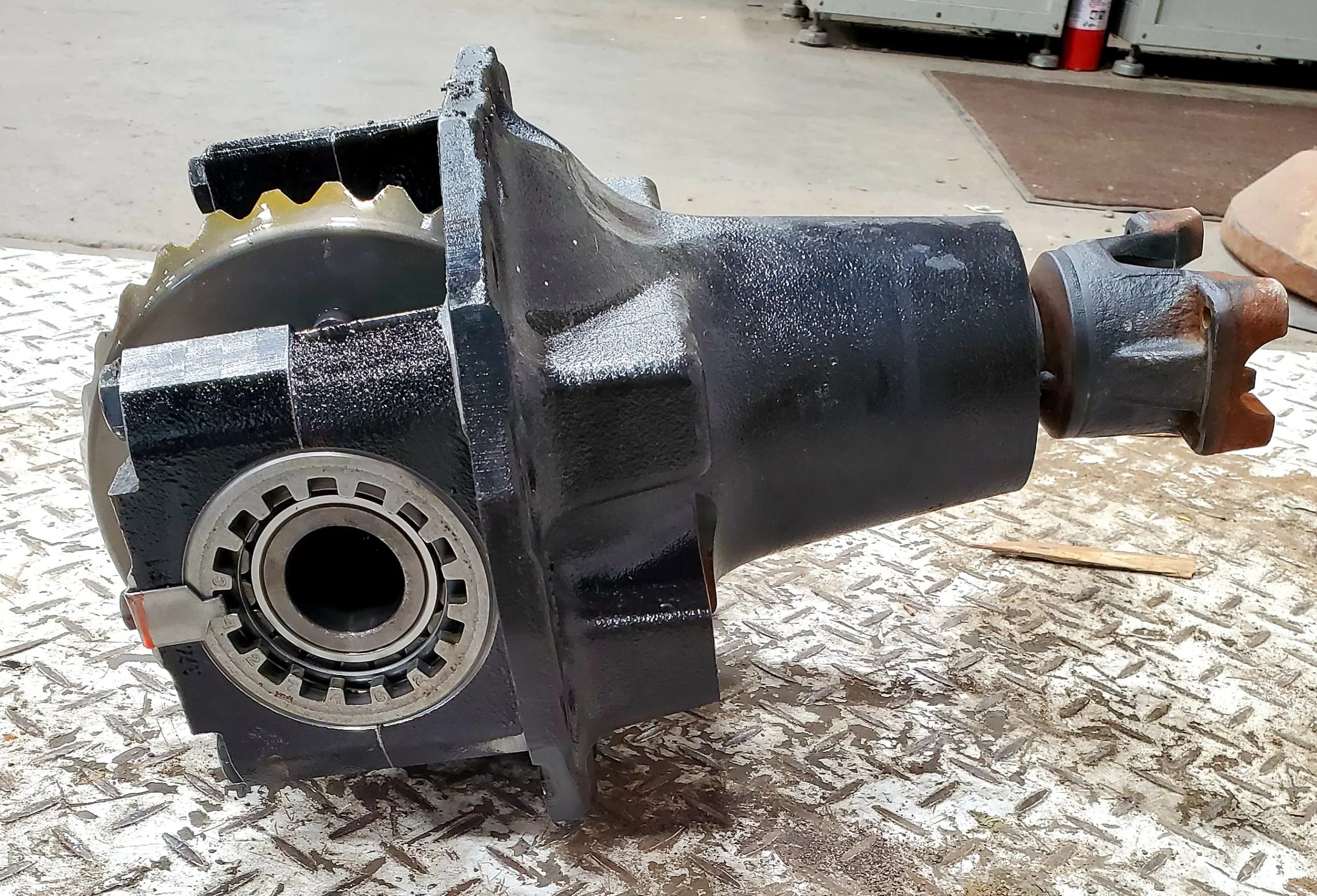

The Massey Ferguson differential assembly is a critical component of many agricultural tractors and machinery, playing a vital role in the overall efficiency and functionality of these machines. This assembly is responsible for allowing the driven wheels to rotate at different speeds, particularly during turns. When a tractor turns, the outside wheel needs to travel a greater distance compared to the inside wheel. A properly functioning differential enables smooth and effective maneuvering, reducing tire wear and improving fuel efficiency.

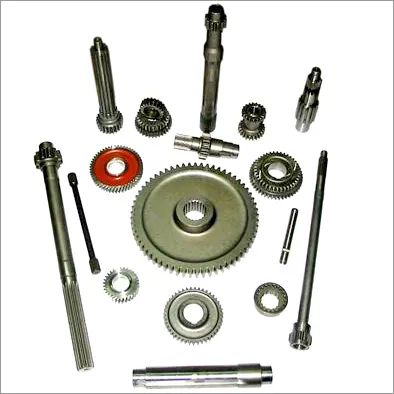

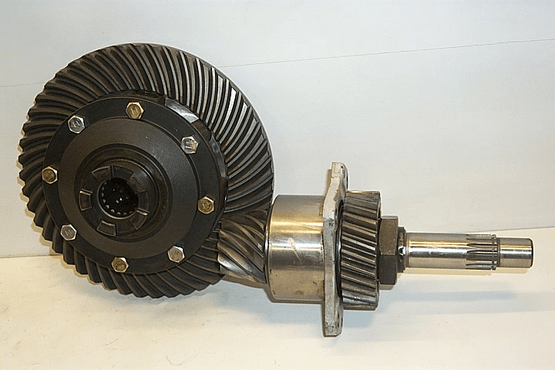

In Massey Ferguson tractors, the differential assembly is engineered for robustness and durability, given the demanding operating conditions of agricultural work. It typically consists of several key components, including the differential gear, pinion gear, and housing. These parts are designed to handle the stress and torque generated by the engine while providing reliability over prolonged usage. Regular maintenance, including checking the lubricant levels and inspecting for wear, is crucial to ensure the longevity of the differential assembly and, consequently, the overall performance of the tractor.

Moreover, advancements in technology have led to enhancements in differential design and performance. Some modern Massey Ferguson models incorporate limited-slip differentials, which provide improved traction in varying soil conditions, ensuring that farmers can work efficiently even in challenging terrains. This technological evolution highlights Massey Ferguson’s commitment to innovation in agricultural machinery, helping operators maximize productivity and reduce operational costs effectively. Understanding the workings and importance of the differential assembly is essential for any tractor operator or maintenance technician, as it directly impacts the machine’s handling and overall effectiveness in the field.