Description

EPR Insulated Power Cable: A Reliable Workhorse of the Electrical Industry

In the vast and complex world of electrical power distribution, the unsung heroes are often the cables that quietly and reliably transmit electricity from source to destination. Among these vital components, EPR (Ethylene Propylene Rubber) insulated power cables stand out for their robust performance and versatility, making them a preferred choice for a wide range of applications.

What is EPR Insulation?

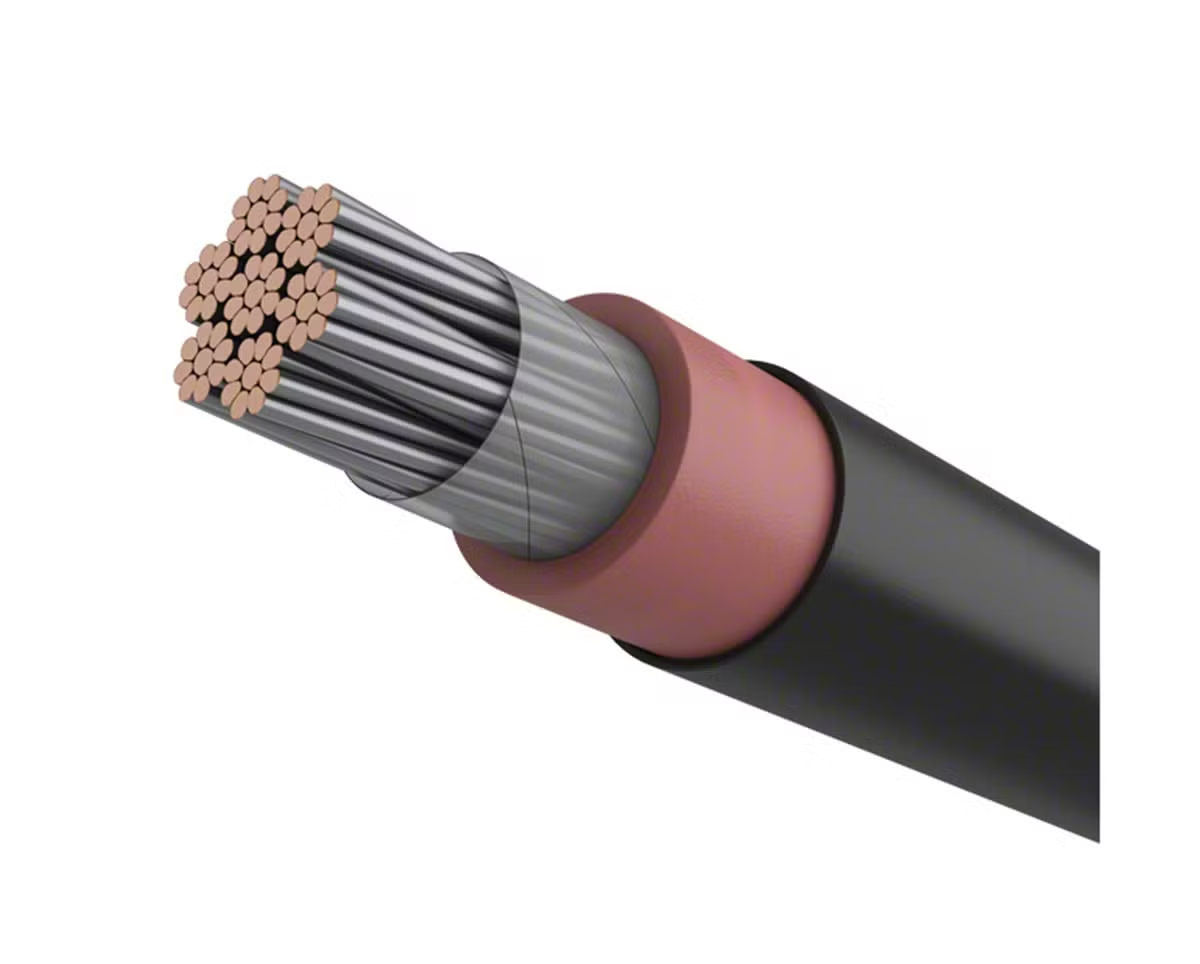

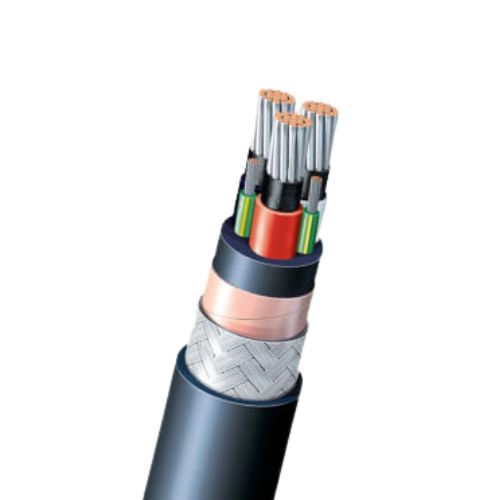

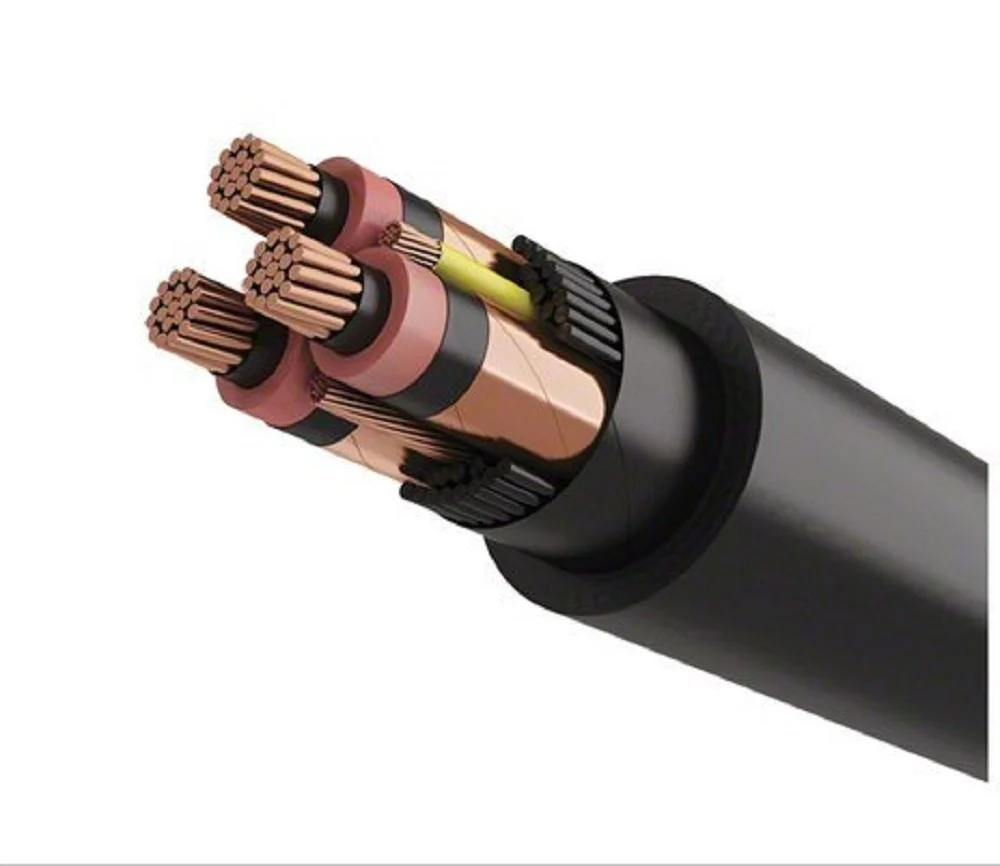

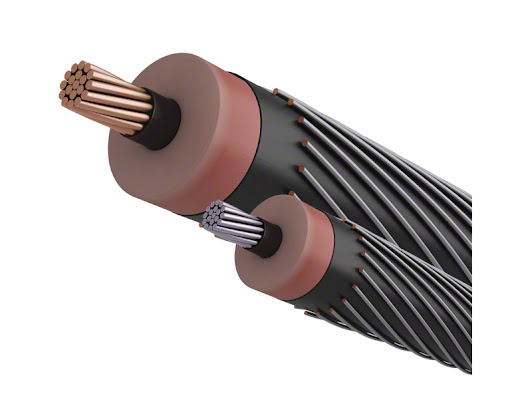

EPR insulation is a thermosetting elastomer renowned for its excellent electrical, thermal, and mechanical properties. Unlike thermoplastic insulation materials like PVC, EPR undergoes a chemical change during vulcanization, creating a cross-linked structure. This cross-linking process imparts enhanced properties, making EPR a superior choice for demanding applications.

Key Advantages of EPR Insulated Power Cables:

EPR insulated power cables offer a compelling combination of benefits, making them a reliable and cost-effective solution for various power distribution needs. Some of the key advantages include:

- Superior Electrical Properties: EPR boasts excellent dielectric strength, resistance to electrical tracking, and low dielectric loss. This ensures efficient and reliable power transmission while minimizing energy waste.

- Exceptional Thermal Stability: EPR insulation can withstand high operating temperatures, typically up to 90°C for continuous use. This allows for higher current carrying capacity and reduced risk of overheating, enhancing the cable’s lifespan and safety.

- Excellent Flexibility and Abrasion Resistance: The inherent flexibility of EPR makes cable installation easier, particularly in tight spaces or complex routes. Furthermore, its resistance to abrasion and physical damage ensures long-term durability in harsh environments.

- Resistance to Environmental Factors: EPR is highly resistant to moisture, chemicals, oils, and ozone, making it suitable for both indoor and outdoor applications. This resistance minimizes the risk of degradation and ensures consistent performance over time.

- Low Temperature Performance: Unlike some other insulation materials, EPR maintains its flexibility and impact resistance even at low temperatures, making it ideal for use in cold climates.

- Long Service Life: The combination of excellent electrical, thermal, and mechanical properties contributes to a long and reliable service life, reducing the need for frequent replacements and minimizing downtime.

Applications of EPR Insulated Power Cables:

The versatility of EPR insulated power cables allows them to be used in a diverse array of applications, including:

- Power Generation: Connecting generators to transformers and switchgear.

- Industrial Plants: Supplying power to machinery, equipment, and lighting systems.

- Commercial Buildings: Powering lighting, HVAC systems, and other electrical loads.

- Underground Distribution: Providing power to residential and commercial areas.

- Renewable Energy Projects: Connecting solar panels and wind turbines to the grid.

- Transportation: Powering electric trains, subways, and other transportation systems.

- Mining and Oil & Gas: Supplying power to equipment in demanding environments.

Considerations When Selecting EPR Insulated Power Cables:

While EPR offers numerous advantages, proper selection and installation are crucial for optimal performance. Factors to consider include:

- Voltage Rating: Selecting the appropriate voltage rating to match the system requirements.

- Conductor Size: Determining the correct conductor size based on the load and distance.

- Insulation Thickness: Ensuring adequate insulation thickness for the operating voltage and environmental conditions.

- Cable Construction: Choosing the appropriate cable construction, including shielding, armoring, and jacketing, based on the application requirements.

- Installation Practices: Following proper installation guidelines to avoid damage to the cable and ensure safe and reliable operation.

Conclusion:

EPR insulated power cables represent a robust and reliable solution for a wide range of power distribution needs. Their superior electrical, thermal, and mechanical properties make them a preferred choice for applications demanding high performance, durability, and long service life. By understanding the benefits and considerations of EPR insulation, engineers and contractors can effectively leverage its capabilities to design and implement efficient and reliable power distribution systems. As the demand for electricity continues to grow, EPR insulated power cables will undoubtedly remain a vital component in the electrical infrastructure for years to come.