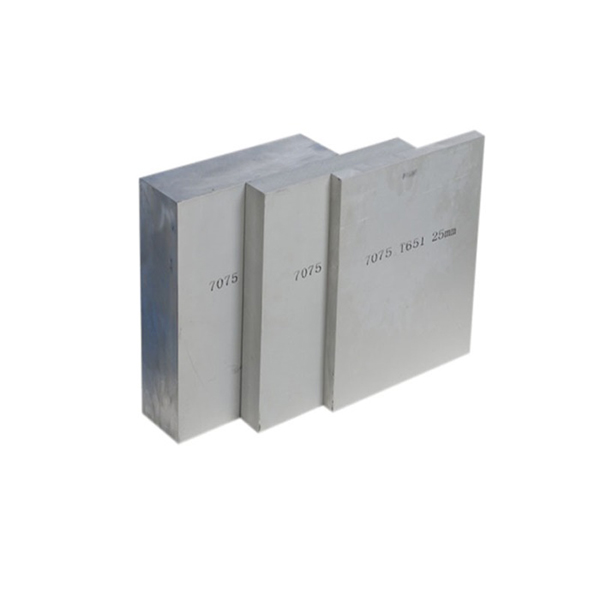

Description

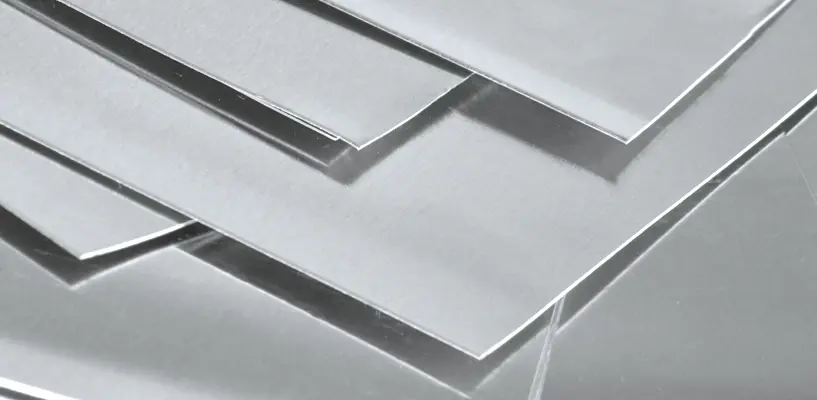

Aluminum 7075 is a high-strength alloy that falls under the category of aluminum-zinc alloys, known for its outstanding mechanical properties and versatility in various applications. This alloy is particularly noted for its impressive strength-to-weight ratio, making it an ideal choice in industries where performance and durability are crucial. Typically, 7075 aluminum is used in aerospace applications, military components, and high-stress automotive parts. Its composition includes zinc as the primary alloying element, along with smaller amounts of magnesium, copper, and other elements that contribute to its strength.

One of the defining characteristics of Aluminum 7075 is its ability to withstand significant amounts of stress and deformation, making it suitable for demanding applications. The heat treatment process enhances its mechanical properties even further, allowing manufacturers to tailor the alloy’s performance to specific needs. However, it’s important to note that while 7075 offers excellent strength, it can be less resistant to corrosion compared to other aluminum alloys, necessitating protective coatings or anodizing treatments for prolonged exposure to harsh environments.

Moreover, the fabrication of Aluminum 7075 presents some challenges due to its high strength, which can lead to difficulty in machining and welding. Despite this, advancements in manufacturing technologies and techniques have made it easier to work with this alloy. Overall, Aluminum 7075 stands out as a premium choice for applications where high strength, low weight, and structural integrity are paramount, making it a preferred material in cutting-edge engineering and design.