Description

Ⅰ Product Description

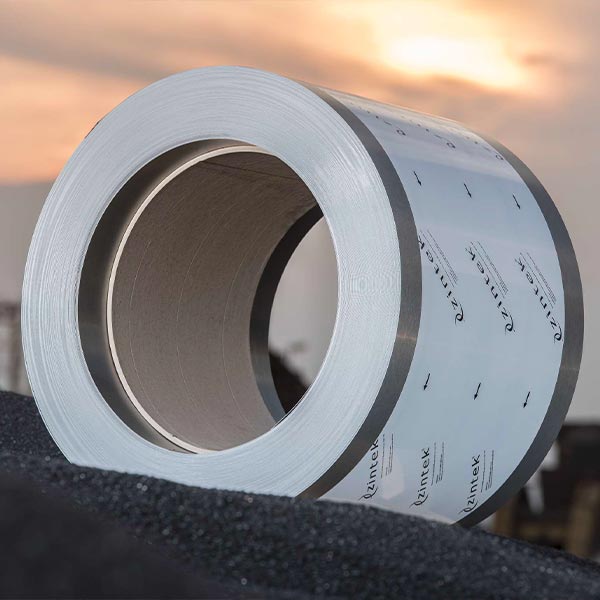

Stainless steel plate is generally the general term for stainless steel plate and acid-resistant steel plate. Its surface is smooth, has high plasticity, toughness and mechanical strength, and is resistant to corrosion by acids, alkaline gases, solutions and other media. It is an alloy steel that is not easy to rust, but it is not absolutely rust-free.

In practical applications, steel that is resistant to corrosion by weakly corrosive media is often called stainless steel, while steel that is resistant to corrosion by chemical media is called acid-resistant steel. Due to the difference in chemical composition between the two, the former is not necessarily resistant to corrosion by chemical media, while the latter is generally stainless. The corrosion resistance of stainless steel depends on the alloying elements contained in the steel.

Ⅱ Technical Parameters

- Product Name: Stainless Steel Plate/Sheet

- Standards: GB, AISI, ASTM, DIN, EN, JIS, SUS, etc.

- Surface Finish: 2B, BA, NO.1, NO.4, 8K, HL, Embossing, Satin, Mirror, etc.

- Grade: 201, 430, 304, 304L, 316, 316L, 310S, 317, 317L, 321, 904L, 2205, 2507, 31803

- Technical Treatment: Cold Rolled, Hot Rolled

- Thickness: Hot Rolled: 2.5mm-200mm; Cold Rolled: 0.3mm – 6mm

- Width: Hot Rolled: 1000mm-3500mm; Cold Rolled: 10mm – 2000mm

- Length: 1000-6000mm(Customized sizes are accepted)

- Thickness: 0.3-4mm cold rolled; 3-100mm hot rolled; Customized according to customer requirements

- Application: Indoor/outdoor decoration, construction areas, elevators, kitchens; ceilings, cabinets, advertising nameplates, roof structures, shipbuilding.

- MOQ: 1 Ton

Ⅲ Stainless Steel Square Sheet Application

Stainless steel plates are widely used in many industries due to their excellent corrosion resistance and strength. Here are some of the main application areas:

1. Construction industry:

– Stainless steel sheets are often used for cladding and roofing of buildings, especially in coastal areas, and are an ideal material for building exterior walls and interior decoration due to their good resistance to salt spray corrosion.

– Stainless steel is used in reinforced concrete, bridge decks, piers and suspension cables in low-rise and high-rise buildings, educational and hospital buildings, sports venues, stations, etc.

2. Industrial equipment:

– In pulp and paper equipment, heat exchangers, machinery, dyeing equipment and film processing equipment, stainless steel plates are widely used due to their chemical resistance.

– Stainless steel plates are also used in the manufacture of pipes, especially in environments where resistance to high temperatures and pressures is required.

3. Medical and food processing:

– Stainless steel plates are used in medical devices and food processing equipment to ensure hygiene and safety by taking advantage of their resistance to rust and ease of sterilization.