Description

As a result of its conductive properties and inertness, tungsten is widely used in electronics and high-radiation environments. It serves as a key source for X-ray targets and finds applications in electrodes, conductors, and metallic films.

1. The Uses of Tungsten in the Field of Alloy

Steel

The hardness of tungsten is very high, and the density of tungsten is close to gold, so it can improve the strength, hardness, and wear resistance of steel. It is an important alloy element and is widely used in the production of various steels.

Common tungsten-containing steels include tungsten steel and tungsten-cobalt magnetic steel with high magnetization and coercive force. These steels are mainly used to manufacture various tools, such as drills, and milling cutters.

Tungsten Carbide-based Cemented Carbide

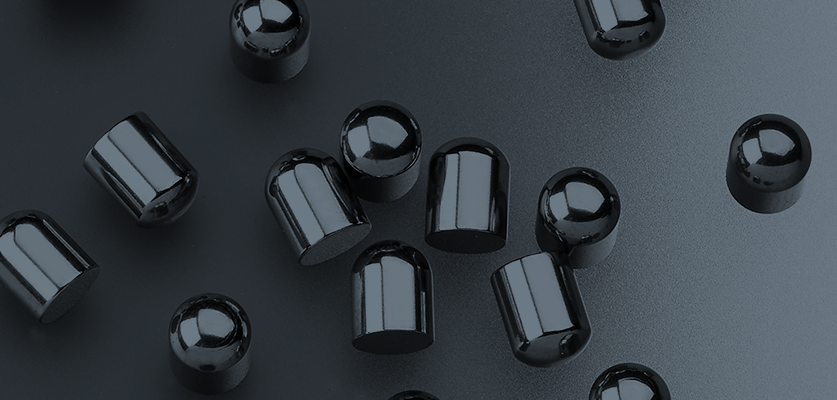

Tungsten carbide has high wear resistance and refractory properties, and its hardness is close to the diamond, so it is often used in some hard alloys. At present, tungsten carbide-based cemented carbide is the largest consumer field of tungsten. This cemented carbide is made by sintering tungsten carbide micron powder and a metal binder (such as cobalt, nickel, and molybdenum) in a vacuum furnace or a hydrogen reduction furnace.

Tungsten carbide-based cemented carbides are roughly divided into four categories: tungsten carbide-cobalt, tungsten carbide-titanium carbide-cobalt, tungsten carbide-titanium carbide-tantalum (niobium) -cobalt, and steel-bonded cemented carbide. These carbides Tungsten-based cemented carbide is mainly used in the manufacture of cutting tools and mining tools.

Heat-Resistant and Wear-Resistant Alloy

The melting point of tungsten is the highest among all metals, and its hardness is also very high, so it is often used to produce heat-resistant and wear-resistant alloys.

For example, alloys of tungsten and chromium, cobalt, and carbon are commonly used to produce high-strength and wear-resistant parts, such as valves for aircraft engines, turbine wheels, etc. And alloys of tungsten and other refractory metals (such as tantalum, niobium, molybdenum, and hafnium) are often used to produce high-strength parts such as nozzles and engines for rockets.

High Specific Gravity Alloy

Due to its high density and high hardness, tungsten has become an ideal material for making high-specific gravity alloys. These high specific gravity alloys are divided into W-Ni-Fe, W-Ni-Cu, W-Co, W-WC-Cu, W-Ag, and other main series according to their composition characteristics and applications.

This type of alloy has the characteristics of high specific gravity, high strength, strong radiation absorption capacity, large thermal conductivity, small thermal expansion coefficient, good electrical conductivity, good weldability, and processable, etc., and is widely used in aerospace, aviation, military, petroleum drilling electrical instrumentation, medical and other industries, such as manufacturing armor, heat sinks, and contact materials such as knife switches, circuit breakers, etc.

2. The Uses of Tungsten in the Field of Electronics

Tungsten has high plasticity, low evaporation rate, high melting point, and strong electron emission ability. Therefore, tungsten and its alloys are widely used in the electronics industry.