Description

General description

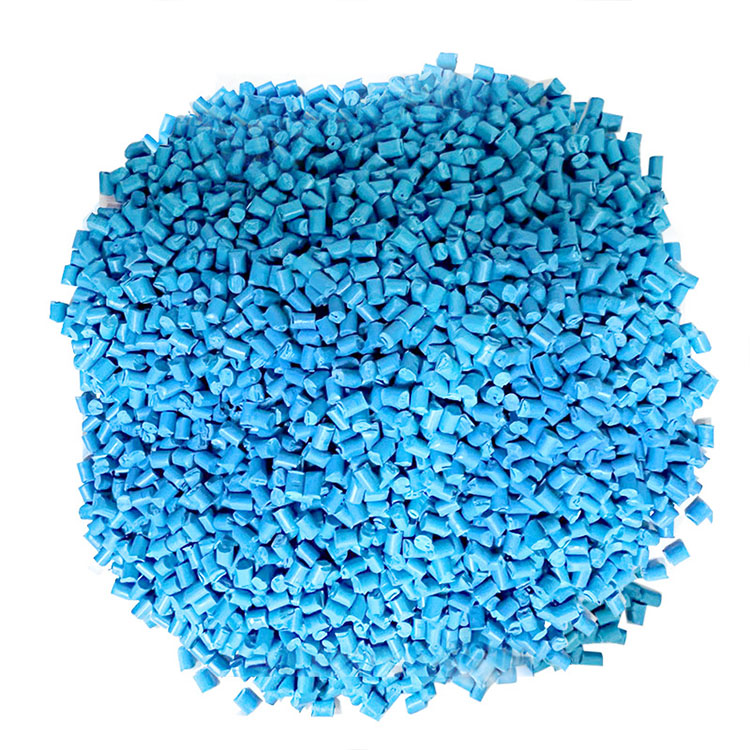

Polypropylene has many similarities to polyethylene, a plastic created by chain polymerisation of ethene, which is a gas very similar to propene. Polypropylene and polyethylene are particularly similar in terms of their electrical properties and solution behaviour. Compared to polyethylene, however, PP has an additional methyl group, which influences some chemical properties and significantly increases the thermal and mechanical resistance. Among standard plastics, PP is the second most commonly used.

Definition

The density of PP is between 0.895 and 0.920 grams per cubic centimetre, so the parts made from it have a very low weight. Polypropylene also has high strength and rigidity. If the plastic is filled with appropriate mineral substances such as talcum or glass fibres, the range of mechanical properties is significantly extended.

Compared to polyethylene, polypropylene has a higher melting temperature. In addition, the maximum temperature to which this plastic can be permanently exposed without becoming unusable is higher. The homopolymer of polypropylene can be used permanently at temperatures between 0 °C and +100 °C. This temperature range can be further increased by copolymerisation.

1 Development

Following the work by Ziegler in Germany, the process for producing “stereoregular” polymers was perfected by Professor Giulio Nattain in Italy. Natta produced the first polypropylene resin in Spain in 1954. Natta utilised catalysts developed for the polyethylene industry and applied the technology to propylene gas.

These new polymers with their ability to crystallise soon became popular and polypropylene is now a very successful product in many areas. Commercial production began in 1957 and polypropylene usage has displayed strong growth from this date. The versatility of the polymer (the ability to adapt to a wide range of fabrication methods and applications) has sustained growth rates enabling PP to challenge the market share of a host of alternative materials in plethora of applications including…

| Type | Product | |

| mouldings | automotive components, sailing dinghies, etc. | |

| fibres | carpets, bailing twine, clothing, etc. | |

| tape | replaced jute | |

| film | biaxially oriented film (OPP) | |

| foam | structural foam, and low density packging (bead process similar to XPS) |

Oriented polypropylene (OPP) has seen considerable growth, having replaced cellophane in virtually all applications.

The properties of Polypropylene include…

- Semi-rigid

- Translucent

- Good chemical resistance

- Tough

- Good fatigue resistance

- Integral hinge property

- Good heat resistance

PP does not present stress-cracking problems and offers excellent electrical and chemical resistance at higher temperatures. While the properties of PP are similar to those of Polyethylene, there are specific differences. These include a lower density, higher softening point (PP doesn’t melt below 160oC, Polyethylene, a more common plastic, will anneal at around 100oC) and higher rigidity and hardness. Additives are applied to all commercially produced polypropylene resins to protect the polymer during processing and to enhance end-use performance.

| Homopol | Copolym | ||

| Density | / kgm-3 | 905 | 905 |

| Price / Tonne | / £ | 680 | 620 |

| Tensile Strength | / Mpa | 33 | 25 |

| Tensile Modulus | / Gpa | 1.4 | 1.0 |

| Elongation at Break | / % | 150 | 300 |

| Hardness | / Rockwell “R” Scale | 90 | 80 |

| Notched Izod Impact | / kJm-1 | 0.07 | 0.1 |

| Heat Distortion Temp (HDT) | @ 0.45 MPa / °C | 105 | 100 |

| Heat Distortion Temp (HDT) | @ 1.80 MPa / °C | 65 | 60 |

| Volume Resistivity | / logÙm | 19 | 19 |

| Oxygen Index | / % | 17 | 17 |

Linear hydrocarbon polymer, little or no unsaturation. Similar to polyethylene in many properties, especially solution and electrical. However, the presence of the methyl group attached to every alternate backbone chain carbon atom can alter the properties in a number of ways:

(i) it can cause a slight stiffening of the chain – increasing the crystalline melting point (Tm);

(ii) it can interfere with the molecular symmetry – depressing crystallinity and hence Tm.