Description

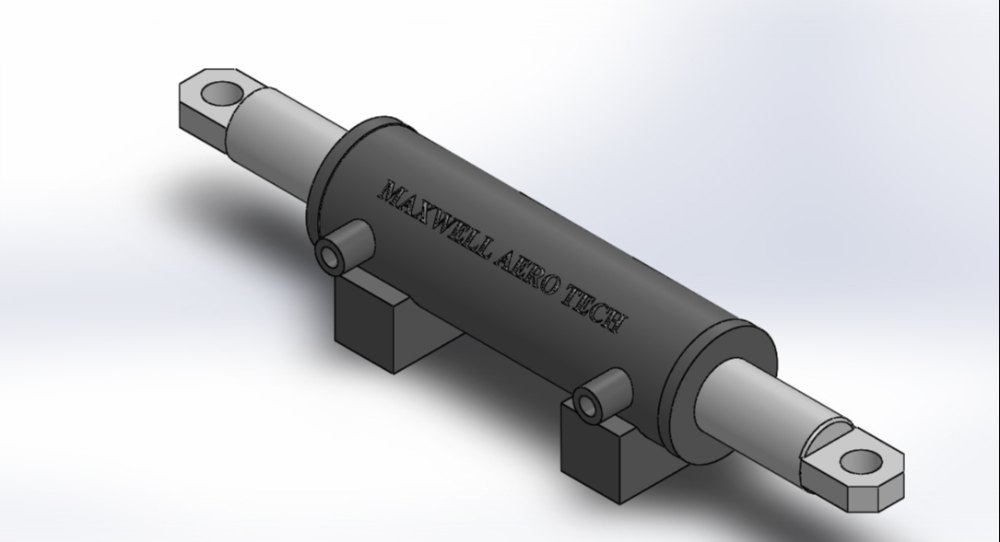

The forklift hydraulic steering cylinder is a crucial component of a forklift’s steering system, enabling precise maneuverability and control. This hydraulic mechanism operates by utilizing pressurized fluid to move the piston within the cylinder, which in turn translates into steering motion. The design of the hydraulic steering cylinder allows for smoother and more responsive handling, especially when navigating tight spaces or when making sharp turns. Unlike traditional mechanical linkages, hydraulic cylinders provide a significant advantage in terms of reducing the effort required by the operator to steer the forklift, which is particularly beneficial in demanding warehouse or construction environments.

One of the key benefits of a hydraulic steering cylinder is its ability to absorb shocks and vibrations, thereby providing a more stable and comfortable driving experience. This is important, as operators often traverse uneven surfaces while transporting heavy loads. The hydraulic system not only enhances the steering capabilities but also contributes to the overall safety of the equipment. By ensuring that the operator can maintain control, the risk of accidents or mishaps during operation is significantly minimized.

Maintenance of the hydraulic steering cylinder is vital to ensure its longevity and efficiency. Regular inspections for leaks, fluid levels, and hydraulic pressure should be conducted to prevent any potential failures that could compromise the forklift’s performance. Additionally, keeping the system clean and free of contaminants can help prolong the life of the cylinder and enhance operational reliability. Understanding the importance of the hydraulic steering cylinder in a forklift can lead to better care practices and ultimately contribute to increased productivity in various industrial settings.