Description

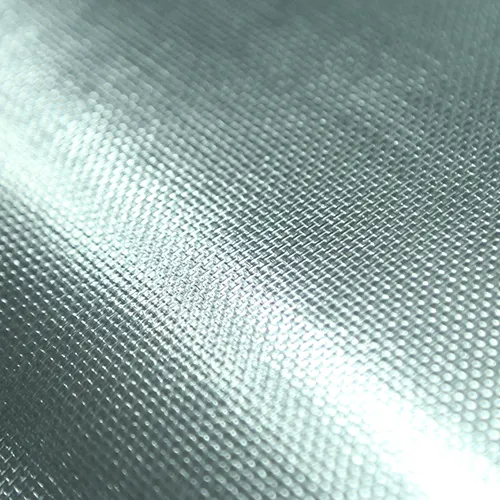

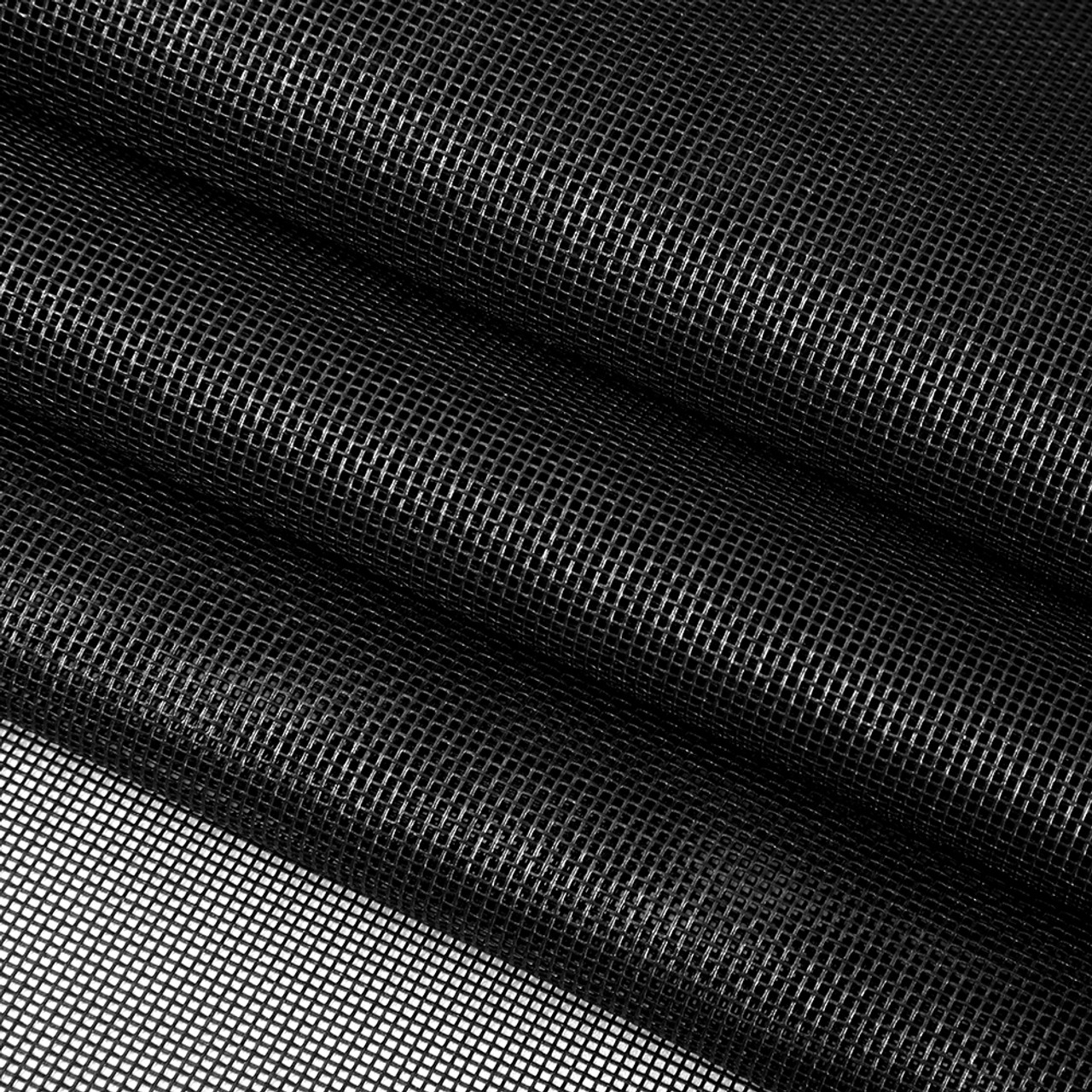

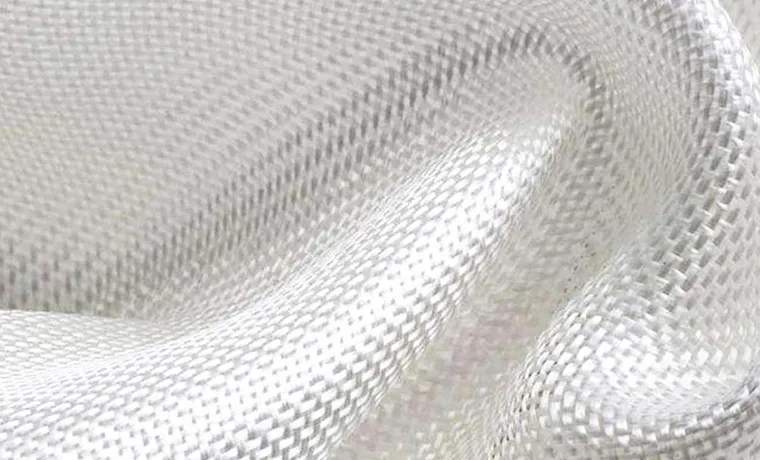

Fiberglass fabric is a versatile and durable material that has gained widespread popularity across various industries due to its unique properties and benefits. Made from woven glass fibers, this fabric exhibits excellent strength-to-weight ratios, making it ideal for applications that require both lightweight materials and robust structural integrity. One of the key advantages of fiberglass fabric is its resistance to deformation, heat, and corrosive substances, making it suitable for use in environments that would typically degrade other materials.

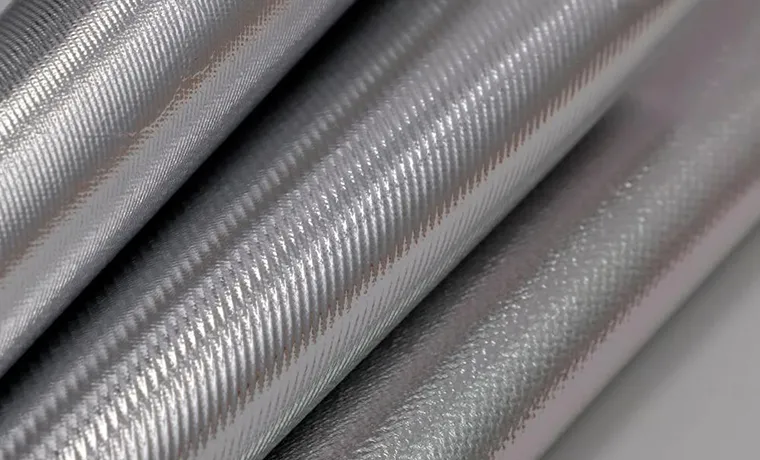

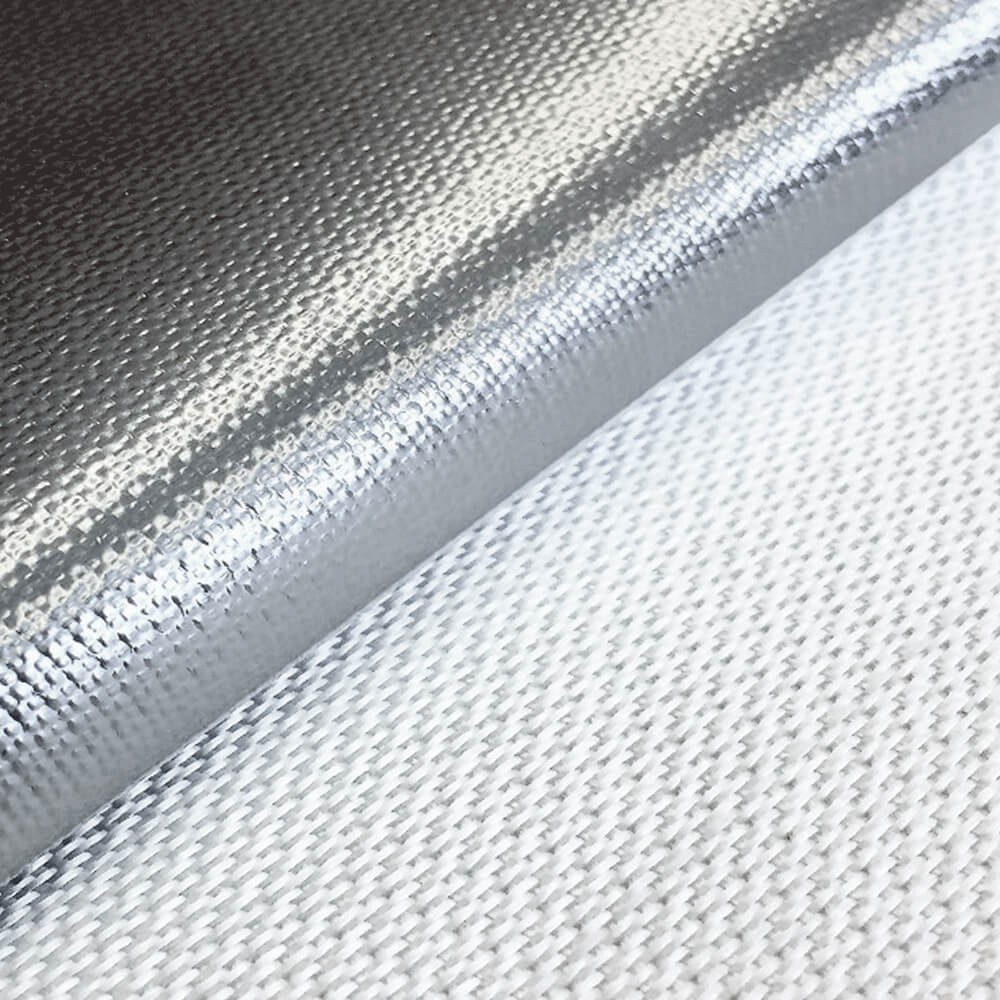

The manufacturing process of fiberglass fabric involves drawing molten glass into fine filaments, which are then woven together to create a cohesive, flexible fabric. This process allows for various weaves and thicknesses, enabling the material to be tailored for specific applications, such as in automotive, aerospace, marine, and construction industries. Additionally, fiberglass fabric can be easily combined with resins to create composite materials, enhancing its strength and performance while providing additional benefits like water resistance and increased impact strength.

Fiberglass fabric also offers a range of aesthetic possibilities, as it can be dyed or coated to achieve different colors and finishes. This versatility not only makes it functional but also visually appealing, allowing designers to utilize it in various artistic and architectural applications. As sustainability becomes an increasing focus in material production, advancements in the manufacturing of fiberglass fabric are leading to more eco-friendly options, such as recycled glass fibers. Overall, the blend of durability, adaptability, and aesthetic appeal makes fiberglass fabric an invaluable resource in modern material engineering and design.