Description

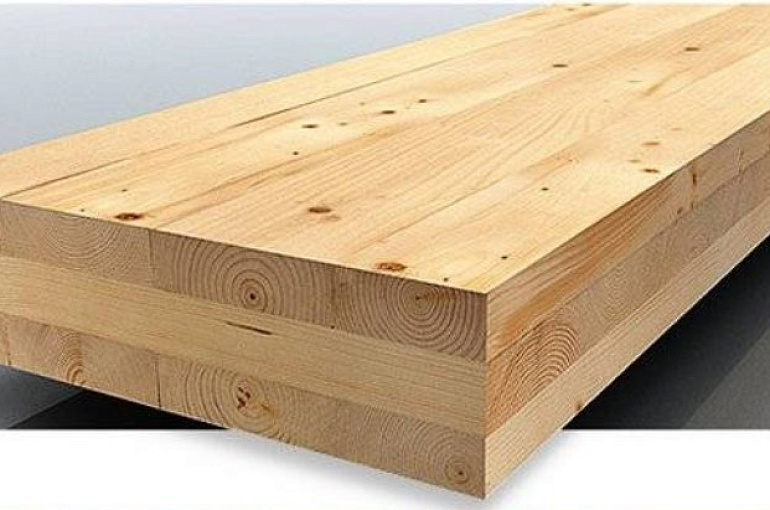

CLT panels consist of layered lumber boards (usually three, five, or seven) stacked crosswise at 90-degree angles and glued into place. Finger joints and structural adhesive connect the boards. Board thickness typically varies between 5/8 inch to 2 inches, with board width ranging from 2.4 to 9.5 inches.The panels can be manufactured at custom dimensions, though transportation restrictions dictate their length.

Alternating grains improve CLT panels’ dimensional stability. This strength affords designers a host of new uses for wood, including wide prefabricated floor slabs, single-level walls, and taller floor plate heights. As with other mass timber products, CLT can be left exposed in building interiors — up to 8 stories in the 2021 IBC, offering additional aesthetic attributes.

Like other mass timber products, CLT can be used in hybrid applications with materials such as concrete and steel. It can also be used as a prefabricated building component, accelerating construction timelines.

How It’s Used

Applications for CLT include floors, walls and roofing. The panels’ ability to resist high racking and compressive forces makes them especially cost-effective for multistory and long-span diaphragm applications.

In structural systems, such as walls, floors, and roofs, CLT panels serve as load-bearing elements. As such, in wall applications, the lumber used in the outer layers of a CLT panel is typically oriented vertically so its fibers run parallel to gravity loads, maximizing the wall’s vertical load capacity. In floor and roof applications, the lumber used in the outer layers is oriented so its fibers are parallel to the direction of the span.