Description

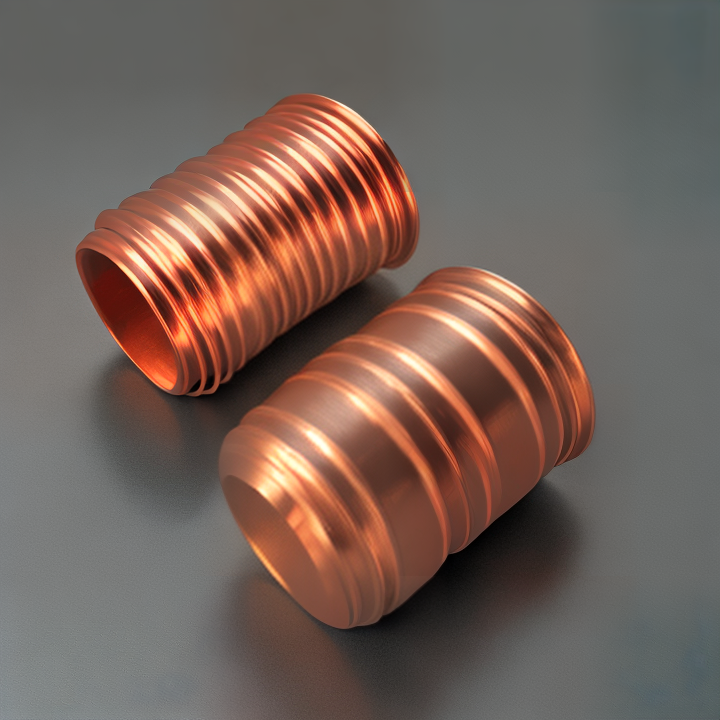

Beryllium copper, specifically the alloy known as C17200, is renowned for its exceptional combination of strength, electrical conductivity, and corrosion resistance. This high-performance alloy is primarily composed of copper and a small percentage of beryllium, which typically ranges from 1.6% to 2.0%. The addition of beryllium significantly enhances the mechanical properties of copper, resulting in an alloy that exhibits a tensile strength comparable to that of some steel grades, while also offering superior thermal and electrical conductivity. This makes C17200 an ideal choice for applications requiring both robust physical characteristics and effective performance in electrical and thermal applications.

One of the standout features of beryllium copper C17200 is its versatility across a wide range of industries. It is commonly utilized in aerospace, telecommunications, and automotive applications, particularly in components such as connectors, springs, and precision instruments. The alloy can also be easily fabricated using conventional machining processes, and it can undergo heat treatment to achieve even greater strength. Additionally, C17200 possesses excellent fatigue resistance and is capable of maintaining its properties under extreme temperature variations, rendering it highly reliable in demanding operating environments.

However, it is worth noting that beryllium is a hazardous material, and special precautions must be observed during metalworking processes to prevent exposure to its dust and fumes. As a result, proper safety protocols and monitoring are crucial when handling beryllium copper. Despite these challenges, the benefits of C17200 continue to make it a favored choice for engineers and designers seeking materials that provide the ideal balance of strength, conductivity, and durability. As technology progresses and demands for advanced materials increase, beryllium copper C17200 remains a pivotal player in the development of innovative solutions across diverse sectors.