Description

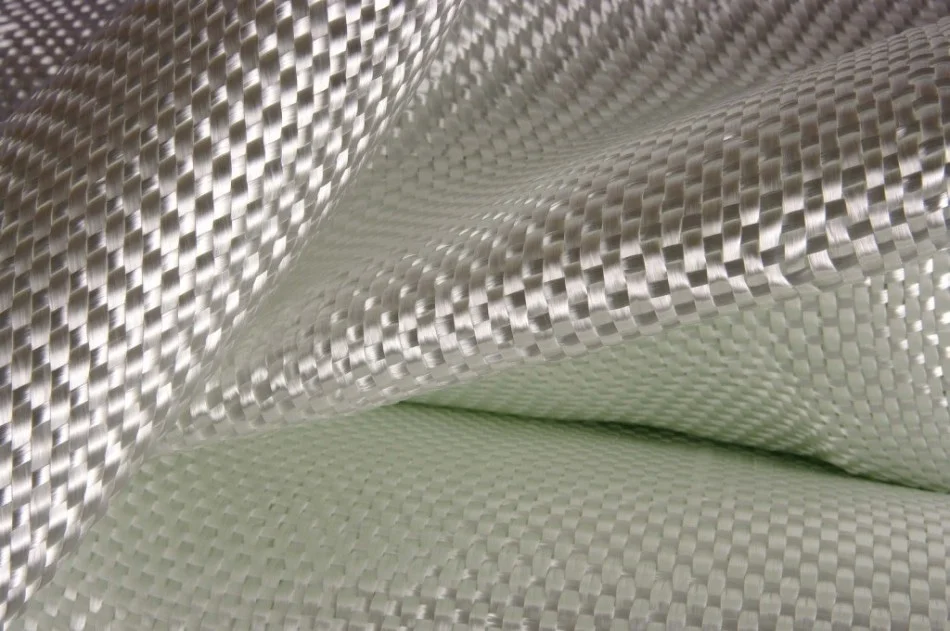

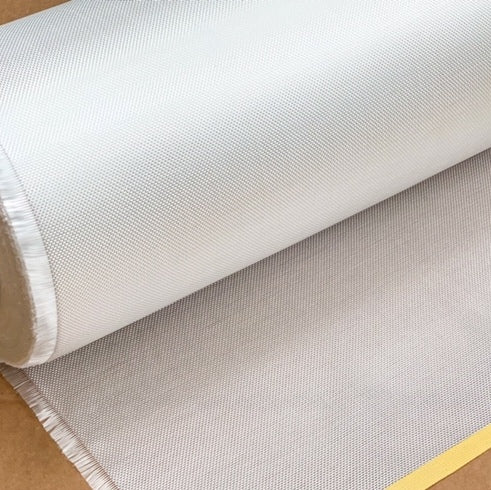

Fiberglass yarn is a specialized material made from finely drawn strands of glass fibers, engineered to create a robust and flexible textile. These yarns are recognized for their exceptional strength-to-weight ratio, resistance to thermal and electrical conductivity, and durability, making them ideal for a variety of applications across multiple industries. Widely used in aerospace, automotive, and construction sectors, fiberglass yarn can reinforce composite materials, providing structural integrity while maintaining a lightweight profile. Its resistance to various chemical agents further enhances its utility, allowing it to perform well in harsh environments where traditional textiles might fail.

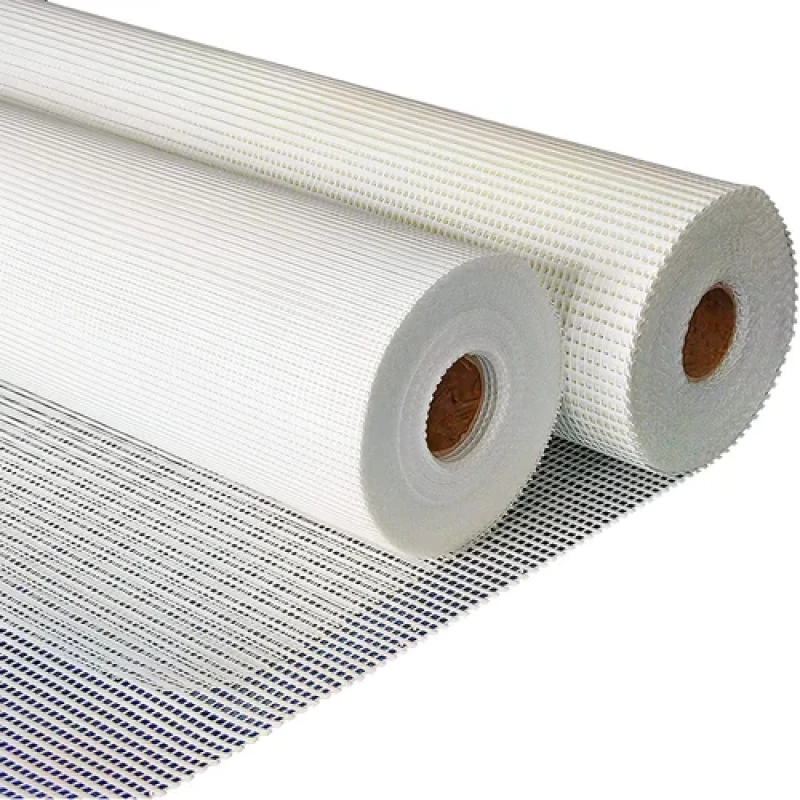

One of the most significant advantages of fiberglass yarn is its versatility in manufacturing. It can be woven or knitted into fabrics, used as a reinforcement in resin systems, or even processed into non-woven mats. This adaptability allows for innovative solutions in producing insulation materials, fire-resistant garments, and even intricate components in electronics. Moreover, with the ongoing advancements in technology, manufacturers are continually improving the production processes of fiberglass yarn, leading to enhanced properties such as flexibility and overall performance tailored to specific applications.

Sustainability considerations are also becoming more prominent in the production and use of fiberglass yarn. As industries aim to reduce their environmental footprint, research and development efforts are focused on creating more eco-friendly production methods and exploring the potential for recycling fiberglass materials. This push towards sustainability is transforming not only the production processes but also the end-of-life management of fiberglass products, ensuring that they are not only functional but also more environmentally responsible. As a result, fiberglass yarn continues to be a key player in the development of advanced materials, balancing performance with sustainability in an ever-evolving market landscape.