Description

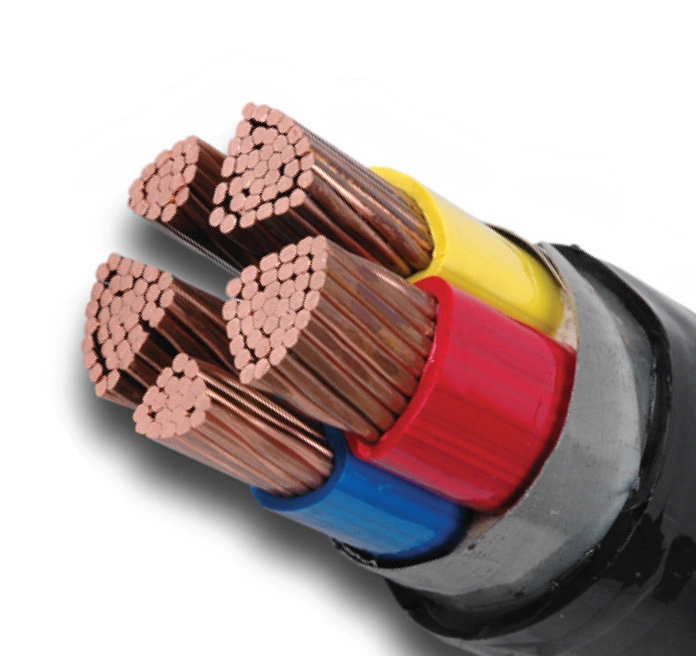

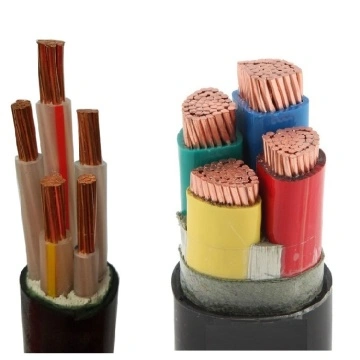

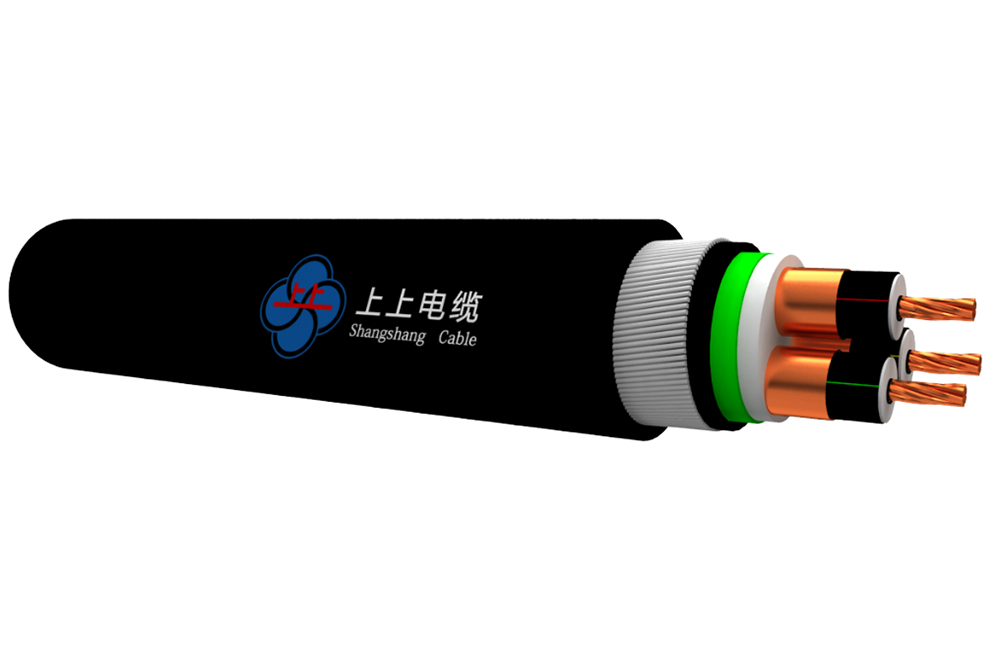

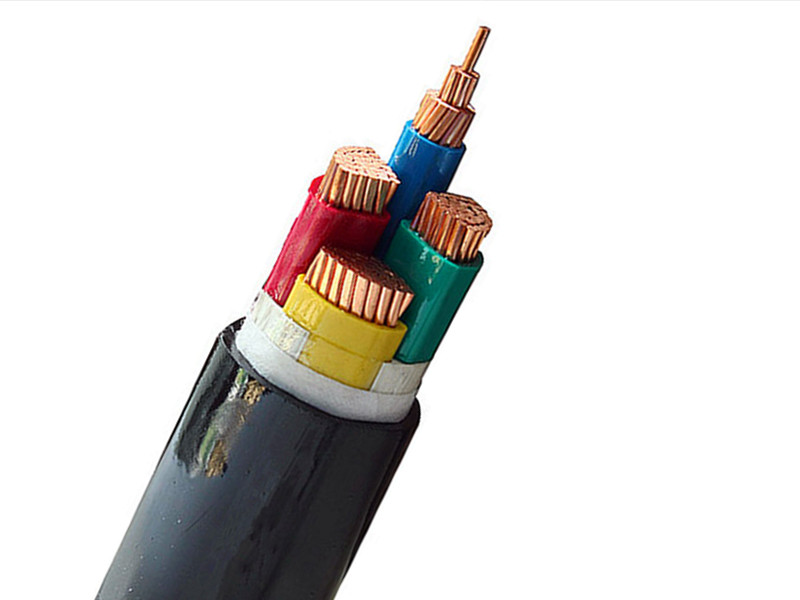

XLPE (Cross-Linked Polyethylene) insulated power cables are essential components in modern electrical systems, known for their superior performance and reliability. XLPE insulation is created through a thermal cross-linking process that enhances the material’s thermal, electrical, and mechanical properties. This innovative insulation technology allows XLPE cables to operate at higher temperatures compared to conventional PVC (Polyvinyl Chloride) insulated cables, making them suitable for applications where resistance to heat and environmental stress is critical.

One of the key advantages of XLPE insulated power cables is their excellent electrical performance. The low dielectric loss and high insulation resistance of XLPE enhance the efficiency of power transmission, reducing energy losses over long distances. Moreover, XLPE cables are highly resistant to moisture, UV radiation, and chemicals, which contributes to their longevity and reduces the need for frequent replacements, thus providing a cost-effective solution in the long term.

In addition to their technical benefits, XLPE insulated cables are also designed with safety and environmental considerations in mind. The materials used in manufacturing are typically halogen-free, which means they emit minimal toxic fumes in the event of a fire. This makes XLPE cables a safer choice for use in residential, commercial, and industrial applications. As energy demands continue to grow and the focus on sustainable practices increases, the role of XLPE insulated power cables in electrical infrastructure becomes increasingly vital, facilitating the transition to greener energy solutions.