Description

Nickel Alloy 600, also known as Inconel 600, is a high-performance nickel-chromium alloy renowned for its exceptional strength and oxidation resistance at elevated temperatures. Composed primarily of nickel (approximately 72%) with significant amounts of chromium (14%) and iron (6%), it features a unique combination of properties that makes it suitable for a wide range of applications in harsh environments. Its ability to withstand high temperatures and resist oxidation and carburization allows it to thrive in applications such as gas turbines, heat exchangers, and chemical processing equipment.

One of the key advantages of Nickel Alloy 600 is its remarkable stability in corrosive environments, particularly in those involving high temperatures and oxidative conditions. This alloy is resistant to various forms of corrosion including pitting, crevice corrosion, and stress corrosion cracking. As a result, it is often employed in the aerospace and nuclear industries, where robust performance is critical. Its excellent weldability and formability also contribute to its popularity in manufacturing complex components that demand both reliability and durability.

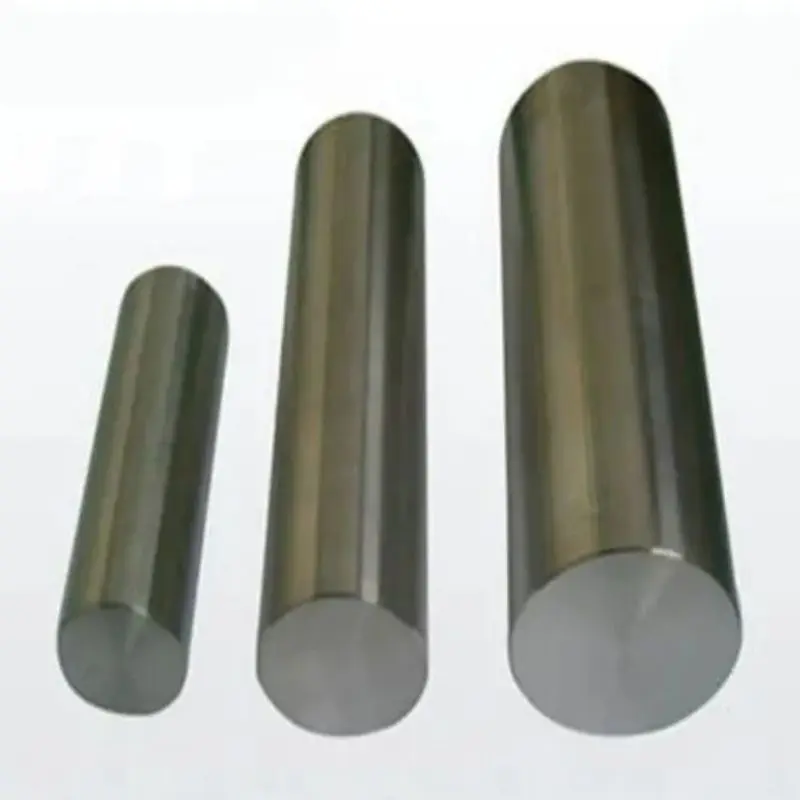

Furthermore, Nickel Alloy 600 demonstrates a high level of versatility which allows it to be customized for specific industrial needs. The alloy can be fabricated into various shapes and sizes through processes such as welding, machining, and casting, making it an ideal choice for tailored solutions in demanding applications. As industries continue to evolve and seek materials that can withstand the rigors of extreme environments, Nickel Alloy 600 remains a prominent choice, underlining its importance in engineering and materials science.